charpy impact test specimen astm|charpy impact test standard pdf : discounter The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample. . For example, when testing steel for use in cold . web21 de jun. de 2023 · Significado dos sonhos: Interpretando sonhos de gravidez pessoal. Sonhar com gravidez é um dos sonhos mais comuns e pode ter diferentes .

{plog:ftitle_list}

WEBTelegram channel 🦶🏻🔞Footjob & Solejob & FootFetish🔞🦶🏻. Chanel link, subscribers, messages (even deleted ones), comments, rating and more. 💃 Subscribers: 9311 Telegram Porn

The following testing parameters have been shown to affect test results significantly: method of specimen fabrication, including but not limited to processing .The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample. . For example, when testing steel for use in cold .

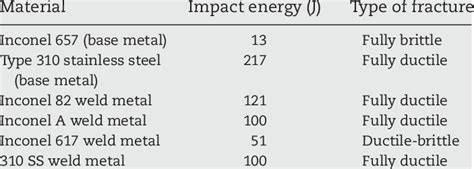

Charpy Impact Test Standards • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials Purpose • To determine the energy required to fracture a v-notched .The apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the material can be inferred by comparing the difference in the height of the hammer before and after the fracture (energy absorbed by the fracture event).According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results .The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load [10]. This test consists of striking a suitable specimen with a .

charpy impact test temperature requirements

charpy impact test standard pdf

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

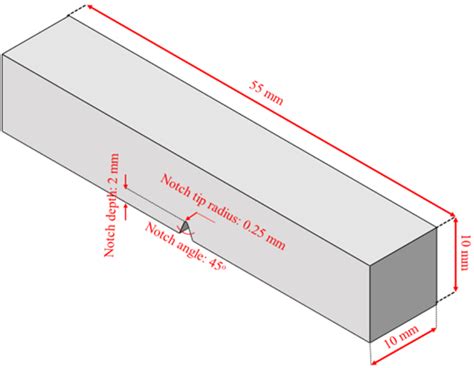

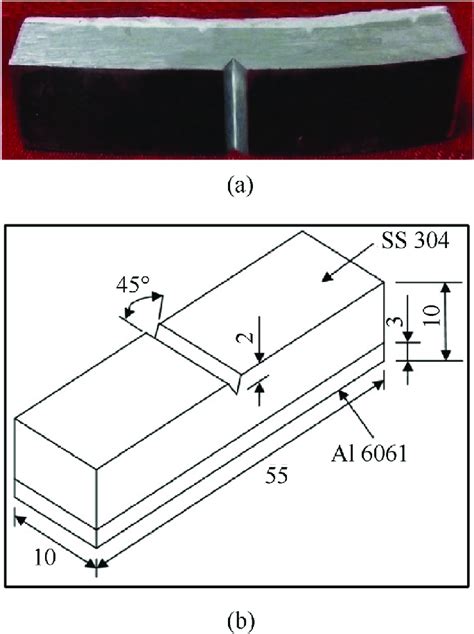

The standard Charpy Impact Test specimen consist of a bar of metal, or other material, 55x10x10mm having a notch machined across one of the larger dimensions. V-notch: 2mm deep, with 45° angle and 0.25mm radius along the .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. . The standard Charpy .

charpy impact test sample dimensions

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations . Any test specimen preparation, conditioning, dimensions and testing parameters required by the materials specification shall ta . Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics D6110-10 .According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significantThe standard test for ASTM D256 requires specimens to be made with a milled notch. This is technically an equivalent standard to ISO 180 – Determination of Izod Impact Strength of Rigid Materials. . Charpy Impact Testing. Izod Impact Testing. Tested Materials . Plastics. Plastics. Types of Notches (0.25mm) Preferred. V-notch . V-notch .

charpy impact test sample

The standard Charpy impact test specimen, as depicted in the procedure section, has dimensions of 55 mm × 10 mm × 10 mm, with a machined notch along one of the larger dimensions. . What Is the Difference Between the Charpy Impact Test and the IZOD Impact Strength Test? According to ASTM E23, the primary distinction between Charpy and Izod .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.ASTM E23 and ISO 148-1 define test methods for Charpy impact testing of notched-bar metallic specimens. ASTM A370 also includes Charpy impact test method requirements but focuses only on steel products. All three standards provide details for properly measuring the energy absorbed by the notched specimen when impacted by a swinging pendulum.CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the . The standard test for ASTM D256 requires specimens to be made with a milled notch. This is technically an equivalent standard to ISO 180 – Determination of Izod Impact .

Specimen size: Specimens are 80 x 10mm by thickness. The specimens can be either notched or unnotched. Data: Impact energy is expressed in joules. Impact strength is calculated by dividing impact energy in joules by the area under the notch. A higher number indicates a tougher material. **Please note that this test description is intentionally . ASTM D6110 Determination of Charpy Impact Properties. . The test is typically uninstrumented and is used to determine the energy required to break the specimen. Different test parameters are specified according to the type of material that the specimen is made of as well as the type of notch cut in it. . (Determination of Charpy Impact .The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials

The Charpy impact test was studied theoretically and experimentally, to learn how much of the pendulum energy is imparted to the test specimen. The fracture was separated from the subsequent collision, and the collision was studied kinematically. . Because of the variability of customs processes and procedures in different countries, ASTM . Significance and Use 5.1 Brown and Lu4,5 show the Charpy impact energy is related to the ultimate critical temperature of the rapid crack propagation [RCP] behavior as measured by the ISO 13477, S-4 test.6 5.2 The test method may be used to determine the

charpy impact test pdf

ASTM E23 standard: discover how Charpy impact tests evaluate the resistance of metals and the energy absorbed by notched samples. +39 02 9098 1113 [email protected]. Home; Company; . V-notched specimens for Charpy testing. The V-notch specimen for Charpy testing is the most common. Standard dimensions include a length of 55 mm, width .

Digital Automatic Polarimeter factories

The smaller specimens permit more specimens to be made from small trial heats and are much more efficient for ir . Specimen Size Effects in Charpy Impact Testing . Because of the variability of customs processes and procedures in different countries, ASTM International cannot guarantee transit times to international destinations. Customs .The Charpy impact test specimen notch faces away from the pendulum, which swings down from a set height to strike the sample. . For example, when testing steel for use in cold climates, the ASTM A370 Charpy impact test can reveal how the material’s toughness decreases as temperatures drop. This information is vital for ensuring that the .

Download scientific diagram | According to ASTM A370 standard, the Charpy impact test specimen of 10 mm × 6 mm × 55 mm size is prepared from the developed jute fiber composite. The test specimen .

Portable Digital Refractometers factories

Engineers and researchers who have specialized Charpy testing needs will be the primary users of two new standards recently approved by ASTM International Committee E28 on Mechanical Testing. The new standards, E2248, Test Method for Impact Testing of Miniaturized Charpy V-Notch Specimens, and E2298, Test Method for Instrumented Impact Testing of Metallic . Determining the Charpy Impact Resistance of Notched Specimens of . ClassiÞcation D4000 lists the ASTM materials standards that currently exist. If there is no material speciÞcation, then the requirements of this test method apply. 5.2 The pendulum impact test indicates the energy to break standard test specimens of speciÞed size under .The standard test method for the Charpy impact resistance of FRP composites can be found in ASTM D6110 [51] and EN ISO 179 [52].This test method can be performed in a fully automated way with a small technical effort, and the specimen can be inexpensively machined.

Identify apparatus and related components used for notched-bar impact testing of metallic materials. Recognize test specimen requirements for both Charpy and Izod specimens. Recall test procedures, including Charpy and Izod test procedures. Recall information obtainable from impact tests. Identify reporting requirements for ASTM E23.

Both methods characterize the impact strength of a material in very similar ways so that the results largely correlate. The Izod test method, in which the specimen is positioned vertically, is normally used in ASTM standards.; The Charpy impact test, which uses a three-point bending arrangement, is the preferred method in ISO standards.; Both methods are used to measure . USA Testing Lab for ASTM D6110 Charpy Impact Resistance of Notched Specimens of Plastics in USA, Indonesia, Philippines, Malaysia, Thailand, Canada, China, India, and all over the World. (302)244-7710 . [email protected] . . ASTM D6110 test specimens are rectangular in shape. The specimens are ensured to be free of surface .Presents worldwide research on the factors and variables of the Charpy test. Consists of 12 papers in sections on The Pendulum-Impact Machine; The Specimen—Notches; The Specimen—Size; and The Test Technique. The store will not work correctly when cookies are disabled. . By downloading the ASTM Document you are entering into a contract . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

Auto Abbe refractometer factories

Thermostat Auto Abbe refractometer factories

web29 de dez. de 2021 · se inscreve no canal : youtube.com/c/GienLiuinstagram @gienliutiktok: @gienhonliu

charpy impact test specimen astm|charpy impact test standard pdf